:

The STM32 microcontrollers offer a wide range of features and functionalities, and one of the key peripherals is the Analog-to-Digital Converter (ADC). The ADC allows the microcontroller to convert analog signals into digital values, making it a crucial component for many applications that require precise measurement and control of analog signals.

In this article, I will provide an in-depth guide on STM32 ADC, from its configuration to reading ADC values and exploring advanced features. Whether you are a beginner or an experienced user, this article will equip you with the necessary knowledge to effectively utilize the STM32 ADC in your projects.

Configuring STM32 ADC

ADC Initialization Process

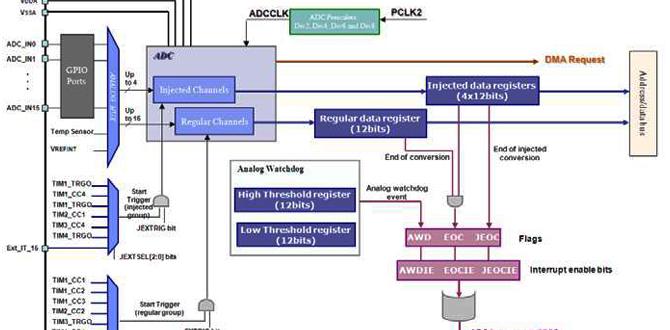

Before using the STM32 ADC, it is essential to initialize the ADC module properly. The initialization process typically involves setting up clock configurations, configuring ADC resolution and sample rate, selecting the number of ADC channels to use, and enabling ADC interrupts if required.

Selection of ADC Channels

The STM32 microcontrollers offer multiple ADC channels, allowing you to measure multiple analog signals simultaneously. You can choose the desired ADC channels based on your application requirements. Each channel has a unique number associated with it, which needs to be configured during the initialization process.

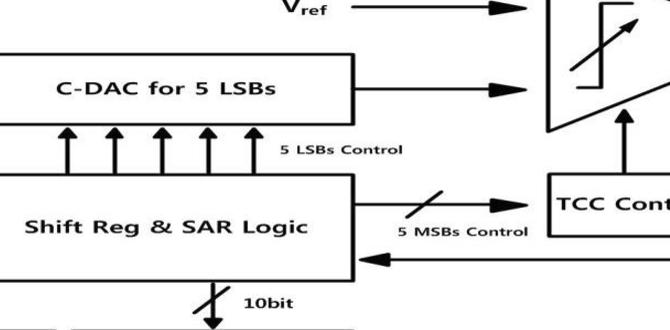

Setting ADC Resolution and Sample Rate

The ADC resolution determines the number of bits used to represent the measured analog signal. Higher resolution provides better accuracy but requires more processing time and memory. You can select the desired resolution based on the precision required for your application. Additionally, the sample rate determines how frequently the ADC samples the analog input voltage. It is important to choose an appropriate sample rate to capture the desired frequency components of the analog signal.

Reading ADC Values

Polling Mode for ADC Conversion

In the polling mode, the microcontroller waits for each ADC conversion to complete before proceeding to the next conversion. This mode is suitable for simpler applications where timing constraints are not critical. The ADC values can be read from the ADC data register once the conversion is complete.

Interrupt-driven Mode for ADC Conversion

In the interrupt-driven mode, the ADC conversions are initiated, and the microcontroller can continue executing other tasks while the conversions are in progress. Once a conversion is complete, an interrupt is triggered, allowing the microcontroller to handle the ADC data. This mode is useful for applications that require real-time processing or multitasking.

Advanced Features of STM32 ADC

DMA Usage for ADC Conversions

The Direct Memory Access (DMA) feature of STM32 microcontrollers can be utilized for ADC conversions. DMA allows the ADC data to be directly transferred to memory without the intervention of the CPU, reducing the CPU’s workload and enabling efficient data transfer. This feature is particularly beneficial for applications that involve high-speed continuous sampling.

Signal Conditioning and Calibration Techniques for ADC

Signal conditioning techniques such as amplification, filtering, and offset adjustment can be applied to the analog signals before feeding them into the ADC. These techniques help improve the accuracy and reliability of ADC measurements. Additionally, the STM32 microcontrollers provide built-in calibration mechanisms to minimize any offset and gain errors introduced by the ADC module.

Troubleshooting and Common Issues

Debugging ADC Issues

When encountering issues with the STM32 ADC, it is essential to follow a systematic debugging approach. This involves checking the ADC configuration, verifying the hardware connections, and ensuring proper initialization routines are implemented. Additionally, using debugging tools and techniques provided by development environments can help identify and resolve any issues efficiently.

Handling Noise and Errors in ADC Readings

Noise and errors can affect the accuracy of ADC readings. To mitigate these issues, proper shielding and grounding techniques should be implemented to minimize external noise sources. Additionally, applying proper signal conditioning techniques and using appropriate voltage references can help reduce errors and improve the overall accuracy of ADC measurements.

Example Applications Using STM32 ADC

Reading Analog Sensors with STM32 ADC

The STM32 ADC can be used to interface with various analog sensors, such as temperature sensors, light sensors, and pressure sensors. By connecting these sensors to the appropriate ADC channels, you can accurately measure and monitor environmental conditions in your application.

Analog-to-Digital Conversion for Audio Signals

Another popular application of the STM32 ADC is audio signal processing. By utilizing the ADC’s high sample rate and resolution capabilities, you can capture and process audio signals for applications such as audio recording, speech recognition, and digital audio effects.

Conclusion

The STM32 ADC is a powerful tool for converting analog signals into digital values. Whether you are working on simple sensor reading tasks or complex audio processing applications, understanding the features and usage of the STM32 ADC can greatly enhance your project’s capabilities. By properly configuring and utilizing the ADC, you can ensure accurate and reliable measurements for your desired applications.

Frequently Asked Questions

Q: Can I use multiple ADC channels simultaneously on STM32 microcontrollers?

A: Yes, STM32 microcontrollers offer multiple ADC channels that can be used simultaneously. You can select the desired channels based on your application requirements.

Q: How can I improve the accuracy of ADC measurements?

A: To improve ADC measurement accuracy, you can apply signal conditioning techniques such as amplification, filtering, and calibration. It is also important to minimize noise sources and ensure proper grounding and shielding of analog signals.

Q: When should I use polling mode for ADC conversions?

A: Polling mode is suitable for simpler applications where timing constraints are not critical. In this mode, the microcontroller waits for each ADC conversion to complete before proceeding to the next conversion.

Q: What is the benefit of using DMA for ADC conversions?

A: Using DMA for ADC conversions allows for efficient data transfer between the ADC and memory without the intervention of the CPU. This reduces the CPU’s workload and enables high-speed continuous sampling in applications.

Q: Can I use the STM32 ADC for audio signal processing?

A: Yes, the STM32 ADC can be used for analog-to-digital conversion of audio signals. With its high sample rate and resolution capabilities, it is well-suited for various audio processing applications.